Can You Use Floor Epoxy On Countertops

- Interior Design

- August 23, 2024

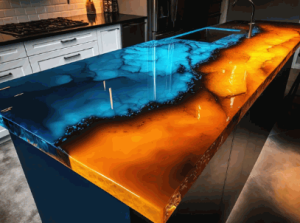

Are you considering a fresh look for your countertops? Floor epoxy might be the solution you’re looking for, offering a durable and decorative finish.

This durable, versatile coating not only offers a sleek finish but can also enhance the longevity of your surfaces, making it an excellent choice for kitchen and bathroom renovations.

Explore the ins and outs of using floor epoxy on countertops, including its benefits, potential risks, and essential preparation steps, such as the use of an acrylic bonding primer.

Find tips for smooth application and maintenance advice, along with alternatives like granite, quartz, and laminate to consider for your DIY projects.

Dive in to discover how to transform your countertops with this innovative approach, utilizing quality epoxy systems and materials!

What Is Floor Epoxy?

Contents

Floor epoxy is a versatile and durable resin-based coating widely used in various applications, providing a protective finish and aesthetic appeal to surfaces such as concrete, wood, and ceramic. It is known for its self-leveling properties, scratch resistance, and heat resistance, making it suitable for high-traffic areas like kitchens and bathrooms. Epoxy coatings come in various types, including high-gloss and decorative finishes, which can enhance the overall look of your space while ensuring long-lasting durability.

Explore further: Does Epoxy Flooring Increase Home Value

Can You Use Floor Epoxy On Countertops?

Yes, floor epoxy can be effectively used on countertops, transforming ordinary surfaces into durable and aesthetically pleasing areas in kitchens and bathrooms. This application offers a glossy, high-shine finish while providing excellent scratch and heat resistance, making it a popular choice for homeowners looking to enhance their countertops with a decorative and functional coating. The use of products like Metallic Marble Epoxy can add unique visual effects.

Yes, floor epoxy can be effectively used on countertops, transforming ordinary surfaces into durable and aesthetically pleasing areas in kitchens and bathrooms. This application offers a glossy, high-shine finish while providing excellent scratch and heat resistance, making it a popular choice for homeowners looking to enhance their countertops with a decorative and functional coating.

What Are The Benefits Of Using Floor Epoxy On Countertops?

Using floor epoxy on countertops offers numerous benefits, including exceptional durability, scratch resistance, and a stunning aesthetic finish that enhances the overall look of your kitchen or bathroom. The self-leveling property of epoxy ensures a smooth, high-gloss surface. This protective coating not only provides a long-lasting surface but also adds value to your home through its ability to withstand wear and tear while making cleaning and maintenance a breeze. Epoxy countertops are also affordable compared to other materials.

One of the standout features of epoxy countertops is their impressive water resistance, which makes them an ideal choice for areas prone to spills and moisture. Unlike traditional materials such as granite or laminate, epoxy is less susceptible to staining and can handle liquids without warping or deteriorating.

The epoxy allows for extensive

- customization options

- visual appeal with a glossy finish

- unique color combinations

enabling homeowners to achieve a personalized look that can harmonize with any interior design.

This type of surface also simplifies upkeep, as it can be easily wiped down with a damp cloth, which is a significant advantage over more porous options like wood that require periodic sealing.

In essence, choosing epoxy countertops not only elevates the functionality of your kitchen or bathroom but also enhances its appearance, providing a contemporary touch that stands out.

What Are The Risks Of Using Floor Epoxy On Countertops?

While using floor epoxy on countertops presents various advantages, there are also some risks involved, including potential surface imperfections and challenges with materials compatibility. Homeowners should be aware of the curing process and the need for proper application techniques to avoid issues such as bubbling, cracking, or peeling, which may necessitate costly repairs.

Ensuring that the application steps are followed accurately is crucial for achieving a flawless finish. Proper surface preparation is a vital aspect of this process, as it lays the foundation for the epoxy to adhere effectively. Consider using a moisture seal to prevent any underlying issues. This includes cleaning the surface thoroughly and repairing any existing damage that could interfere with the bond.

- Consider seeking expert advice for best practices in mixing and applying the epoxy.

- Material compatibility should never be overlooked, as using inconsistent materials can lead to unforeseen complications.

- Do not hesitate to consult resources that address common issues, such as improper mixing ratios that can lead to ineffective curing.

By taking these steps, you can greatly mitigate risks and ensure that your countertop transformation is both stunning and durable.

How To Prepare Countertops For Epoxy Coating?

Preparing countertops for epoxy coating involves a series of essential steps to ensure a smooth and successful application. Proper preparation includes cleaning the surface thoroughly, sanding to create a suitable profile for adhesion, and repairing any chips or cracks using the appropriate materials. This meticulous approach not only enhances the bonding of the epoxy but also contributes to achieving a flawless finish once the application is complete.

What Materials Do You Need?

To prepare countertops for epoxy coating, you will need several essential materials, including cleaning supplies, sanding tools, and a repair kit for any chips or cracks. Epoxy products like Floor Patch Epoxy Gel can be particularly useful for repairs. Having safety equipment such as gloves and respirators is crucial to ensure a safe application process while working with epoxy products. The viscosity of the epoxy can also affect the ease of application.

In your quest for an ideal finish, it’s important to consider a few other tools and materials that facilitate both efficiency and quality. High-quality epoxy resin is paramount, as it not only dictates the durability of the coating but also affects the aesthetic appeal. Xtreme Polishing Systems offers a range of products that are highly recommended. A well-reviewed brand like West System Epoxy is frequently recommended; you can find it at hardware stores or online retailers.

You will also require:

- masking tape for clean edges,

- a heat gun to help eliminate bubbles,

- mixing containers to adequately prepare your epoxy mixture, and

- cleaning agents such as denatured alcohol to ensure a debris-free surface.

Having these materials at hand will streamline your process and enhance the overall quality of your finished project while ensuring safety and effectiveness throughout the application. For added durability, consider using a Polyaspartic Top Coat.

How To Clean And Sand The Countertops?

Cleaning and sanding the countertops is a critical step in surface preparation for epoxy coating, as it ensures proper adhesion and a flawless finish. Begin by thoroughly cleaning the surface to remove any grease, dirt, or debris, followed by sanding to create a smooth and slightly roughened surface that promotes better bonding of the epoxy during application.

To effectively clean the countertops, start with a solution of warm, soapy water and utilize a sponge or cloth to scrub the surface gently. Pay special attention to corners and seams where dirt may accumulate.

Rinse thoroughly with clean water to ensure no soap residue remains, which could hinder adhesion. Next, allow the surface to dry completely before proceeding.

Once the countertop is clean, select a sandpaper with a grit between 60 to 120. Use a sanding block or an orbital sander for even pressure, and begin sanding in circular motions. This will help in avoiding creating deep scratches while achieving the desired texture.

Remember to frequently check your progress and vacuum the dust off the surface periodically. For a decorative touch, you might add a decorative floor flake.

- Tip: Avoid applying too much pressure during sanding; this could damage the countertop.

- Tip: Always wear a mask and eye protection to prevent inhalation of dust particles.

Following these steps diligently ensures that the surface is adequately prepared for the epoxy coating, enhancing durability and appearance.

How To Repair Any Chips Or Cracks?

Repairing any chips or cracks in the countertops is essential before applying epoxy, as it ensures a smooth and uniform surface for the coating. Utilize appropriate epoxy products, such as Floor Patch Epoxy Gel, to fill in any imperfections, allowing for a seamless transition once the epoxy coating is applied.

To begin the repair process, carefully inspect the countertop for any visible damage. It’s advisable to clean the area thoroughly, removing any dust or debris.

Afterward,

- mix the epoxy according to the manufacturer’s instructions, ensuring that the ratio of resin to hardener is correct for optimal durability.

- Next, use a putty knife to apply the mixed epoxy into the chipped or cracked areas, smoothing it out to create an even surface.

- Once applied, allow the repair to cure for the recommended time to achieve maximum strength.

Before proceeding with the epoxy coating, lightly sand the repaired areas to blend them with the surrounding surface. This will help create a flawlessly integrated finish, ensuring that the repaired sections meet the standards of a professional-looking result.

How To Apply Floor Epoxy On Countertops?

Applying floor epoxy on countertops is a straightforward process that requires attention to detail to achieve a high-quality finish. Follow precise application steps including mixing the epoxy components as per instructions, pouring the mixture onto the surface, and spreading it evenly to ensure a uniform coating that enhances durability and aesthetics while providing a protective finish. Consider products from brands like Stone Coat for best results.

Applying floor epoxy on countertops is a straightforward process that requires attention to detail to achieve a high-quality finish. Follow precise application steps including mixing the epoxy components as per instructions, pouring the mixture onto the surface, and spreading it evenly to ensure a uniform coating that enhances durability and aesthetics while providing a protective finish.

What Are The Steps To Follow?

When applying floor epoxy on countertops, it is crucial to follow a systematic approach that includes several key steps to ensure a successful application. Start by mixing the components as per the instructions provided by the epoxy manufacturer, followed by pouring the mixture onto the countertop and using a roller or brush to spread it evenly across the surface.

For a flawless finish, timing is essential; work quickly after mixing to prevent premature curing. Maintaining the right temperature, ideally between 70-80°F, allows the epoxy to flow smoothly. Following expert advice and guidelines will also contribute to a successful project. Ensure the area is well-ventilated and free of dust to avoid imperfections.

- Common Mistakes to Avoid:

- Forget to prep the surface thoroughly – Clean and sand as necessary.

- Neglect to mix properly – Follow the manufacturer’s ratios precisely.

- Overapply – A thin, even coat is better than a thick one.

Monitoring the curing process is vital; follow the guidance on curing time to achieve optimal hardening and durability. If you notice bubbles, use a heat gun gently to pop them, ensuring a pristine final look. Additionally, using products like Floor Patch Epoxy Gel can help in surface repair effectively.

What Are Some Tips For A Smooth Application?

To achieve a smooth application of epoxy on countertops, including products like Stone Coat, there are several key tips to keep in mind, including proper mixing techniques, environmental conditions, and the use of the right tools. Ensuring that the workspace is well-ventilated and free from dust will also contribute to a flawless finish and enhance the overall quality of the epoxy application.

It’s vital to monitor the ideal temperatures and humidity levels during the curing process, as these factors significantly influence the final result.

For optimal performance, temperatures should ideally fall between 70°F to 80°F (21°C to 27°C), while humidity levels should stay below 60%. Patience is paramount when working with epoxy; allowing adequate curing time not only ensures a hard, durable surface but also minimizes the risk of imperfections. Using UV inhibitors can further enhance the longevity and appearance of the epoxy.

Consider the following tips:

- Use a heat gun or torch briefly to eliminate bubbles after application.

- Avoid working on windy days to prevent dust from settling on the wet surface.

- Let each layer cure fully before applying the next coat for the best outcomes.

By adhering to these recommendations, one can enhance the longevity and appearance of the countertop, leading to stunning results that truly shine. These refinements can significantly boost your home value as well.

How To Maintain Epoxy Coated Countertops?

Maintaining epoxy-coated countertops is essential for ensuring their longevity and preserving their aesthetic appeal. Regular cleaning with safe and suitable products, along with taking preventive measures to avoid scratches and heat damage, will help keep your countertops looking pristine while extending their lifespan. Utilizing high gloss finishes can add an extra layer of protection and shine to your countertops.

What Cleaning Products Are Safe To Use?

When maintaining epoxy countertops, it is crucial to use cleaning products that are safe and effective, ensuring that they do not damage the coating. Mild dish soap mixed with water or a pH-neutral cleaner is recommended for routine cleaning while avoiding harsh chemicals and abrasive scrubbers that could compromise the integrity of the epoxy surface.

To keep these surfaces looking pristine, regular maintenance plays a significant role. Users should consider incorporating both homemade solutions and commercial cleaners into their cleaning regimen. For those preferring DIY options, a mixture of vinegar and water can be effective for gentle cleaning, but it’s important to dilute it properly to avoid any potential damage. Exploring products from companies like Xtreme Polishing Systems can also offer specialized solutions for maintaining epoxy surfaces.

- Homemade Cleaner: Combine 1 part vinegar with 3 parts water for an effective, natural cleaning solution.

- Commercial Options: Look for products specifically designed for epoxy or stone surfaces, as they’re formulated to provide the necessary gentle cleaning without causing harm.

- Regular Wiping: Utilizing a microfiber cloth can help prevent scratches and residue buildup.

Staying proactive with cleaning routines not only enhances the appearance of these countertops but also extends their lifespan.

How Often Should You Reapply Epoxy?

Reapplying epoxy on countertops is not necessarily required on a fixed schedule, but factors such as daily wear and tear, use, and environmental conditions will determine how often it should be done. Generally, homeowners should monitor the condition of their epoxy coating and consider reapplication every 3-5 years or when signs of wear, such as scratches or dullness, become apparent. Products like Polyaspartic Top Coat can be an excellent choice for reapplication, offering superior durability and finish.

Recognizing the right moment for a refresh is crucial. Aside from the obvious visible damage on the surface, indicators may also include fading colors, a lackluster appearance, or a rough texture that feels abrasive to the touch. These signs can signal that it’s time to act.

- To assess the need for reapplication, homeowners should regularly inspect their countertops under different lighting conditions to catch any subtle changes.

- Utilizing a soft cloth to gauge texture can also help identify areas that require attention.

When preparing the surface for a new coat, it’s essential to clean it thoroughly, removing any debris or oils that could interfere with adhesion. Light sanding may be beneficial to create a roughened surface, allowing the new epoxy to bond more effectively. Following these steps ensures a successful reapplication and extends the lifespan of this durable finish.

Are There Any Alternatives To Using Floor Epoxy On Countertops?

Yes, there are several alternatives to using floor epoxy on countertops, including materials like quartz, laminate, and ceramic, each offering its own unique benefits and drawbacks. While these options may provide diverse aesthetic choices and varying levels of durability, understanding their pros and cons is essential for making an informed decision based on your specific needs and preferences.

What Are The Pros And Cons Of Other Countertop Coatings?

When considering other countertop coatings, it is essential to weigh the pros and cons of materials such as quartz, laminate, and ceramic, as each has distinct performance characteristics and aesthetic appeal.

Each material presents unique features that can influence the overall success of a home improvement project. For example, while quartz countertops provide a non-porous surface that resists staining and scratches, making them an ideal choice for busy kitchens, the initial investment can be higher compared to laminate options. On the other hand, laminate is economical and available in numerous colors and designs, but it may not withstand heat or heavy impacts as well as quartz can. For those looking for unique styles, Metallic Marble Epoxy offers an artistic and durable alternative.

- Durability: Quartz scores high with exceptional longevity, while laminate’s lifespan may be shorter.

- Maintenance: Quartz requires minimal upkeep, contrasting sharply with laminate that can chip and discolor.

- Cost: Though quartz is pricier, its durability and low maintenance can justify the expense. Laminate is budget-friendly, but its aesthetics might not appeal to all.

- Aesthetic Appeal: Quartz offers a sleek, sophisticated look, while laminate can mimic other materials but often lacks the same depth and quality.

Ultimately, these factors significantly shape the selection of countertop materials tailored to individual preferences and needs.